KC761 User Energy Correction

The KC761 uses a complex temperature compensation algorithm to compensate for temperature-induced drift with good results. However, the coupling between the crystal and the light-sensitive element will drift with time, and the temperature compensation measures cannot solve this kind of optical path change problem. Therefore, the sensor has also taken additional measures to stabilize the spectrum, such as the brightness reference composed of a high-voltage constant-current source, LEDs, etc., which can theoretically compensate for the drift of the optical path. However, for reliability reasons, the KC761 is very restrained in its use of spectral stabilization measures and does not usually turn them on or rely on them.

The optical path drifts naturally with the passage of time, and this drift begins immediately after the sensor is manufactured, is more rapid in the first few weeks, and becomes moderate over time. Instruments that have undergone 4 weeks of aging prior to calibration have passed through the worst of the drift, but aging cannot be extended indefinitely, and there will still be significant leftward drift of energy from the factory, typically around 1%, and up to 5% in the most significant cases.

After the instrument is activated, the energy scale should be calibrated at least once a year. When conditions permit, it should be further shortened, and it is recommended to calibrate it once in January, March and June since the date of commissioning. If the instrument has been subjected to severe impact, dropped, etc., it should be calibrated before further use.

The best way to calibrate is to use a source with a known energy, especially 137Cs. However, this is often difficult to obtain due to regulations and other factors. As an example, we will use the more common calibration using a 241Am ionized smoke detector and 40K in potassium salt.

Materials

(1) Ionized smoke detector, remove the plastic shell, do not need to remove the aluminum shell.

(2) A large bottle of potassium salt. Supermarkets can buy “low-sodium salt”, the main ingredient is potassium chloride.

Methods

(1) Turn on the KC761 in a temperature-stabilized environment and enter the SPEC mode. Place the instrument on the ion smoke sensor, accumulate a long time (usually takes half an hour), and use the cursor to read the energy value of the 241Amγ peak near 59keV, noted as n.

(2) Clear the spectrum, place KC761 close to the potassium salt, accumulate for a longer period of time (usually takes one hour), and read with the cursor the energy value of the 40K peak near 1460keV, noted as k. If the peak is not obvious, set the curve optimization function to level 2 (TRACE-ADV-OPTIM).

(3) In the FUNC menu, find Radiation Sensor Correction and Energy Correction, enter the Probe energy offset (Eo) and Probe energy scaling value (Ez).

Calculations

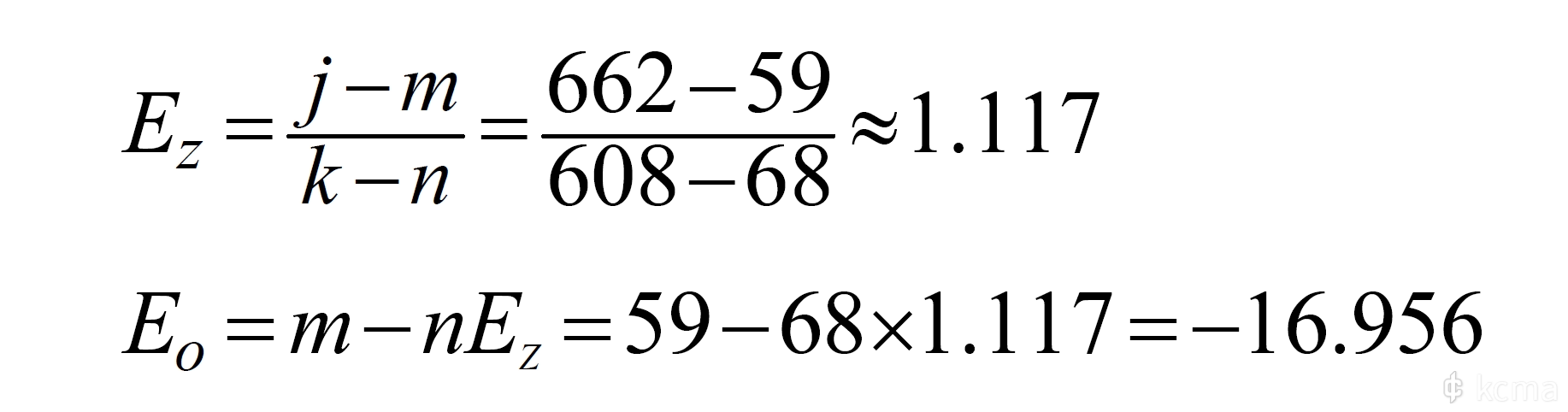

For example, if the known energy of one source is 59keV (named m),the measured energy is 68keV (named n); and the known energy of another source is 662keV (j), the measured energy is 608keV (k), then calculate the scaling factor (Ez) and the offset value (Eo) according to the following formula:

Since Ez is expressed as a percentage in the instrument, 111.7% should be entered in the above example.

In the case of two known sources, the energy of one of them should be located as far as possible in the low-energy range of 30 to 300 keV, while the other source should be located as far as possible in the high-energy range of 500 keV to 1.5 MeV, and the energy difference between them should not be too small. When this condition is met, revisions can also be made using nuclides with at least two peaks that are far apart, for example using thorium oxide (232Th). 137Cs can be used if the instrument is capable of displaying a low-energy peak of 137Cs (a plastic-shelled source is required).

The accuracy of the two-peak revision approach is close to that of sending it back to the factory for calibration.

If there is only one known source, set up energy scaling only. Measure the known source with the instrument and read the all-around peak energy with the cursor peak finding function. Divide the known energy of the source by the energy read to get the scaling factor, which can be entered into the instrument as a percentage.

If the instrument is equipped with multiple gamma sensors, each sensor is tested and entered separately.